GISON Portable Sink Hole Cutting Machine - Easy. Fast. Low Cost. All Shapes Allowed

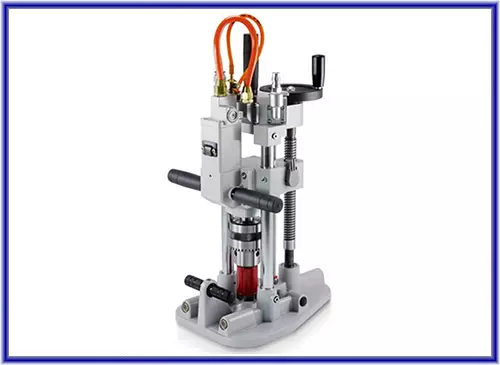

Portable Sink Hole Cutting Machine For Granite, Marble, Stone Material

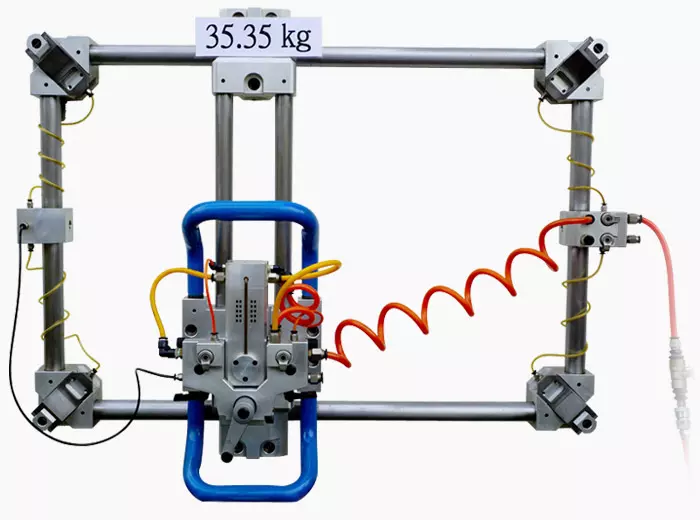

Vacuum Suction Cup – Portable Sink Hole Cutting Vertically And Horizontally

GISON unveils new selection of portable sink hole cutting machine

GISON is providing a reasonable price for you to cut a sink hole in a fast and safe way. Your business would benefit because of the low-cost, and you would also become more competitive in the stone market. Making a sink hole in a stone, granite or marble countertop with GISON's newly developed portable sink hole cutting machine is fast, easy and the cost is a lot lower.

After over 40 years of experience in the air pneumatic tool industry, 10 years with 3 generations of sink hole cutting equipment development, GISON has developed a portable sink hole cutting machine with total solutions.

1st air powered portable sink hole cutting machine designed by GISON ten years ago.

Old fashioned sink hole making

Back in the old days, sink hole in the kitchen can be done using a hard router template, a circular saw and a polisher, by hand, but it takes a lot of concentration and skill. It can also be done at the factory. The process, including sending a design to a CNC machine, picking up a large slab, cutting the slab into a smaller pieces, putting it on a CNC machine to cut a hole and in the end polishing, is conducted. Overall, it's expensive and time-consuming.

2nd generation of air-powered portable sink hole cutting machine

Air power portable sink hole cutting machine - one person operation

GISON's Portable Sink Hole Cutting Machine is a one finger operation machine. It requires no skill or experience. The performance is exact and accurate. There's no need to fix the hole after it's been done, as long as you have the right measurement with you. When you produce more, your business grows.

Mini and portable CNC cutting machine

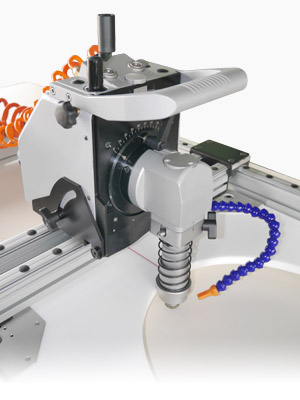

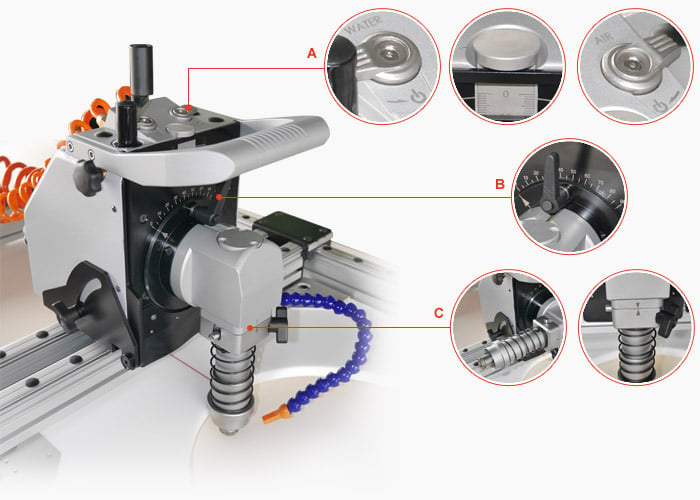

There's no extra jig needed to hold the router, it allows self-control grinding speed, custom-design router template to meet various shapes, easy diamond router bit removal, vacuum suction positioning, and manual control grinding speed. Furthermore, sawing and grinding function is also applied by just simply switching the components.

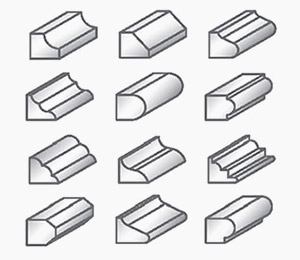

All shapes of sink hole with designed router template

How precise is it? GISON's sink hole cutting equipment comes with a hard router template; all you need is spin the wheel and grind along the template. If you wish to cut a rectangle or square shape, no router template is required. Just set up the length and width (1cm radius round angle).

Once the size is adjusted, the sink hole is cut 100% accurately. With 2cm diamond grinding bit, GISON's portable sink hole cutting machine is capable of cutting any shape. For a smoother corner, GISON's Wet Air Edge Profiling Machine, GPW-510A, is suitable for your final finish up.

Vacuum suction positioning – milling everywhere

You can pick up the router table and wheel it around easily. GISON's portable sink hole cutting machine is equipped with four vacuum suction pads on each corner; once the vacuum suction function is turned on, the whole sink hole cutting machine stays firmly on the surface, whichever you want it to be - floor, wall, slab or countertop. It means you can cut sink holes vertically and horizontally, which is space-saving and time-saving.

Powerful granite sink hole cutting and drilling equipment

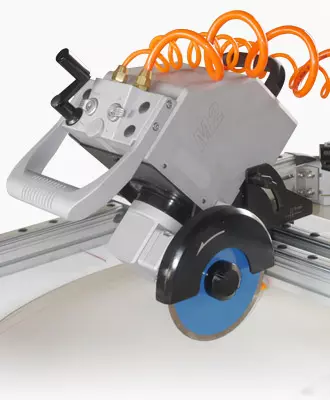

It is a 3 in 1 portable sink hole cutting machine. It allows you to rout just like a plunge router, to grind and to saw in just one purchase by simply by switching the component between backing pad, diamond router bit and circular saw.

3rd generation of air power portable sink hole cutting machine looks better, lighter and more efficient

How to Operate GISON's Air Powered Portable Sink Hole Cutting Machine to Cut a Sink Hole

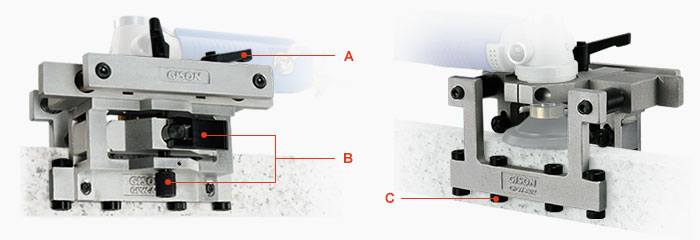

There are locks for each different part, a lock for the diamond router bit, a lock to regulate the grinding area, which is located on both sides of the router table, a lock for a hard router template and a lock to clamp down the router table.

GISON's portable sink hole cutting machine is suitable for drilling holes on stone with any shape.

Place a sink hole template within router table. Set up the routing range by fastening the locks on both sides of router table. Turn on vacuum suction, press down the black flips on each of the four corners in order to secure the router table. If flipping up, there are wheels to move around. Because of the vacuum suction, the router table is attached to the surface solidly. The indicator chart shows the suction pressure.

Second:Turn the diamond bit so it's facing down. Turn on water spray function. Now you can grind by holding the black turning wheel. Even with the high speed rotation, the diamond router bit is still spinning steady and firm. For hole cutting, diamond bit is suitable for marble and granite. To switch diamond router bit, GISON's easy-to-switch design allows the user to place a new one in a minute.

Buying one portable sink hole cutting machine can help you to complete various jobs; it can be used to cut sink holes, mill metal plates and cut stones or tiles.

The portable sink hole cutting machine designed by GISON can grind metals.

The hand held portable sink hole cutting machine can be used to cut stones and tiles.

(A). switch for air motor/water

(B). for changing the measurement of cutting

(C). for changing diamond tool and cutting

Features of GWP-M2A2

- 3-in-1 application: hole drilling, sink hole cutting with a mold and industrial cutting. Allow operation on stone, unlike other computer controlled machine that takes lots of space.

- Allows operation on stone, unlike other computer controlled machines that take lots of space.

- Mold is not needed for rectangle cutting (1cm radius).

- Compact device, it can put on slab to operate. Unlike large former plate or computer-controlled machine needs to occupy a lot of space.

- Fast installation on slab by vacuum suction without any exter clamps. The vacuum suction works real time onto the surface, so the object can't be moved.

- Fast and reliable cut the required shape by template, without repeated renovation, most people can operate, saving time / cost.

- Easy and Quick to setup the moving range of working head.

- Quick installation / replacement diamond bits.

- Adjustable the volume of water.

- The unique torque sensitive cutting speed characteristics of the pneumatic tool, can reduce slab cutting rupture chances.

- We can follow user's require to produce any size (Length x Width).

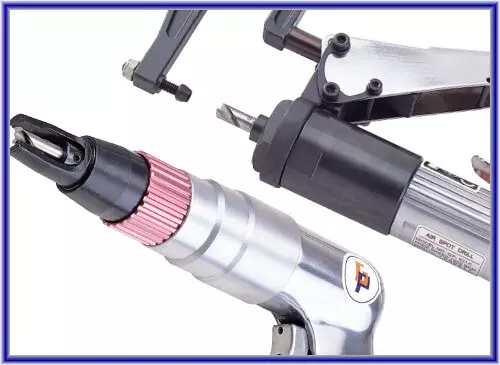

Handheld air tools you need for fast & easy edge profiling

For professional stone processing experts who wish to reduce their workload, GPW-510A: Handheld Pneumatic Profiling Machine, A01: Beveling Auxiliary Base, and A02A: Edge Polishing Auxiliary Base are suitable tools for you to increase profiling precision and speed, as well as lower costs.

GISON handheld pneumatic profiling machine - GPW-510A

After conducting a sink hole cutting, powerful and purposeful profiling equipment is the next air tool you need to scrape the edge. Whether you are working on stone, marble or granite, you need to take care of the various thicknesses that are inherent in all stone slabs. GISON's GPW-510A is a handheld pneumatic profiling machine that allows you to perform high precision edge shaping.

Through relentless development and research, GISON's profiling equipment provides aggressive grinding; wet stone profiling, edge 45 and 90-degree beveling, 9,000 rpm high speed, compressed air and water tubes, interchangeable router bits, swivel bracket for easy operation, adjustable heights, and curved and smooth surfaces. It is lightweight (14.5 kgs), time-saving, safe, has steady positioning, and is long lasting. With GPW-510A, you can use it for slanting, angular and offset stone edge shaping, with or without the swivel bracket.

(A). Regulator with 0-35mm diamond disc wheel height adjustment

(B). Gear lubricant meter

(C). Switching knob for diamond bit or other bits

(D). Sliding rail for inserting the profiling machine (GPW-510B)

(E). Air / water switch

Back in the day, using handheld pneumatic profiling equipment could be cumbersome. First off, because of the mud generated by water and dust; second, the shaping performance relied on user’s capability. As a result, the process was time-consuming and unpredictable.

Through pushing, milling and water spreading, GISON's handheld stone profiling air tool (GPW-510A) amazes you with easy operation. Regardless of whether it’s a construction site or factory, the light weight air tool allows you to move effortlessly. Its depth adjustment controls how far you go, no more human error. And the profiling is done fast by choosing a proper router bit for the right material. There are router bits for stone, marble, and granite with various edges. Best of all, they are reasonably priced!

Attaching the handheld pneumatic profiling machine with a rail bracket (GPW-510B) allows you to perform effertless profiling job with accuracy.

GPW-510 wet air edge profiling machine (GPW-510A + GPW-510B)

GISON Air Tools GPW-A01 -

Beveling Auxiliary Base (15-45°) for Easy Sanding Job

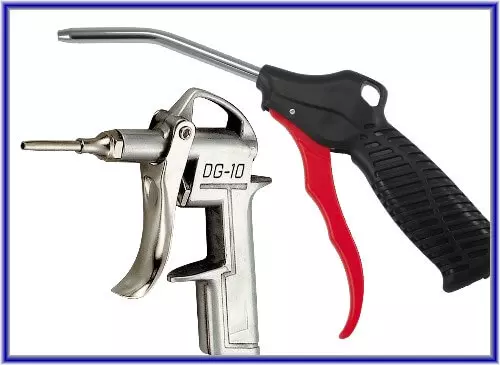

Normally, large stones are cut by CNC cutting machines at the plant for easy shipping, and at the same time, sanding is conducted using large sanding equipment. Once delivered to the construction site, stone pieces are glued, and handheld air tools are used for different jobs such as cutting, drilling, sanding and profiling.

For example, a wet air sander / polisher can help to remove the glue and sharpen the edge. However, sanding can be tiring, and it can cause a wavy look. Thus, GISON has designed a Beveling Auxiliary Base to ensure a sustainable sanding quality. There's no more guesswork on whether it's uneven or not. Using a wet air sander / polisher with beveling auxiliary base allows for high performance sanding. From 15 degrees to 45 degrees, once the beveled edge is set, you can just sand the edge without any concerns. It is great for preparing surfaces for seamless countertop installations.

Fixture is the only difference between GPW-A02B and GPW-A01.

GISON Air Tools GPW-A02A - Edge Polishing Auxiliary Base for 90° Sanding

If you need an air tool to perform 90 degree sanding on stones like tiles, granite, marble, quartz and manmade rock, besides buying an handheld orbital random sander from GISON, you can also consider getting an Edge Polishing Auxiliary Base for assistance. To sand stone edges effortlessly, along with a handheld wet air sander with suitable grit number diamond wet polishing pad, you need a base for the sander to sit tightly on the edge. With edge polishing auxiliary base, you will be able to sand accurately without making a dent or ruining the surface.

- Specification of GPW-A02A

- Polishing thickness : 5~40mm

- Max. pad size : 3" (75mm)

- Weight : 1.29kgs

(A). Fix the clamp width and avoid overtightening, when facilitates moving.

(B). Polishing Depth Control : (max: 5mm) Enable to adjust/control the polishing depth, to avoid over-polishing which may cause uneven surface on the workpiece.

(C). 18 rolling wheels to facilitate moving.

GISON Air Tools GPW-A02B - chamfering & 90° Sanding

GPW-A02B has the same functionality as GPW-A02A except it's the extension of GPW-A01. To perfrom chamfering and 90 degrees sanding, you can just simply install the fixture of A02B onto GPW-A01 to do so.

- Specification of GPW-A02B

- Polishing thickness : 5~50mm for 4" psd, 5~35mm for 3" pad

- Max. pad size : 4" (100mm)

- Weight : 1.62kgs

GPW-A02A: Edge Polishing Auxiliary Base For 90° Sanding

GPW-A01: Beveling Auxiliary Base (15-45°) For Easy Sanding Job

Fixture is the only difference between GPW-A02B and GPW-A01.

Next : Industrial Vacuum Pick-Up Hand Tool

Previous : GISON orbital random sander – air tools

Article sections

- GP-VR120 Linear Sliding Rail Guide is an auxiliary tool for you to enhance your straight line work on various flat surfaces.

- GISON Portable Drilling Machine With Vacuum Cup

- GISON Drill Stand with Vacuum Suction Base - GPD 233, GPD 233S, GPD-234

- GISON orbital random sander – air tools

- GISON Portable Sink Hole Cutting Machine - Easy. Fast. Low Cost. All Shapes Allowed

- Industrial Vacuum Pick-Up Hand Tool

- GISON Pneumatic Tool Process

- 40 Years Of Air Pneumatic Tools Supply – GISON Machinery Co., Ltd.

- Handheld Pneumatic Tools - GISON

- GISON Pneumatic Tool Applications

- Heavy Duty Air Pneumatic Tool Product List

- Contact GISON For A Quote!

- Send A Pneumatic Tool Inquiry Now To Get Best Quote!

- GISON Machinery Co., Ltd. Privacy Policy

Search product